Your cart is currently empty!

Blog

-

Transferring Injection Molds Back to the U.S.

Are you out-sourcing injection molded products in Asia and concerned with the risk?

The manufacturing world has been under a great amount of stress from effects of the Corona Virus. COVID-19 put a dent into companies everyday work flow. The ability to purchase items from other countries and the way your company operates has been altered. All this change caused serious brainstorming, to find a way around the roadblocks put into place by COVID-19. The biggest roadblock for the injection molding industry has been how to continue running when your mold has been delayed from the virus’s effects on China’s import and export of goods.

The manufacturing world has been under a great amount of stress from effects of the Corona Virus. COVID-19 put a dent into companies everyday work flow. The ability to purchase items from other countries and the way your company operates has been altered. All this change caused serious brainstorming, to find a way around the roadblocks put into place by COVID-19. The biggest roadblock for the injection molding industry has been how to continue running when your mold has been delayed from the virus’s effects on China’s import and export of goods.Transferring molds from China back to the United States has been a huge topic Pre-COVID-19. Tariffs, IP theft, and economies of scale are the largest factors that determine whether mold transfers from China are in your company’s’ best interest. Every

company’s situation is different, but do not let the idea of transferring your mold back to the U.S. scare you.

company’s situation is different, but do not let the idea of transferring your mold back to the U.S. scare you.The process of transferring your mold is not only scary, but it can also delay in your production as well. Transferring a mold from one supplier to another can take between two and six weeks, however, at Performance Plastics we have done it in three weeks. We are skilled in the art of mold transfer, especially since half of the customers we currently have started out by transferring their mold to us. Mold transfer is not a small task, but it can be an easy one when you are working with the right company.

To learn more about how Performance Plastics can help transfer your mold, contact Rich Reed, our Vice President of Sales and Marketing, at (513) 321-8404 or RReed@performanceplastics.com.

-

Product Spotlight – EnduroSharp® Scraper Blade & Holder Kit

The product line for EnduroSharp® has changed the way aerospace maintenance professionals remove sealants and adhesives from substrates and fasteners. EnduroSharp® tools are made from Torlon®, a high strength polymer, creating a non-metallic scraper tool that will not damage composite

structures during use. The EnduroSharp® lineup consists of a variety of scraper blades, gap blades, reamers, cutter, bits, and discs for removal of adhesives on aircrafts. The product line even consists of kits containing all of the parts and sizes that you will need.

structures during use. The EnduroSharp® lineup consists of a variety of scraper blades, gap blades, reamers, cutter, bits, and discs for removal of adhesives on aircrafts. The product line even consists of kits containing all of the parts and sizes that you will need.The EnduroSharp® Scraper Blade & Holder Kit is one of the most popular kits ordered. This kit includes the standard scraper blade holder, pocket scraper blade holder, and 2 scraper blades of each size. EnduroSharp® Torlon® Scraper Blade (TSB) inserts come in 5 different sizes, TSB-170, TSB-230, TSB-500, TSB-750, and TSB-1200. The blades slide and lock into the detent pin of the standard scraper blade holder handle, to easily alternate between the sizes as needed. This kit also contains the pocket scraper blade holder for use of the scraper blades in smaller areas.

The EnduroSharp® Scraper Blade & Holder kit is just one of the kits offered in the EnduroSharp® Product line. Contact Rich Reed for our Vice President of Sales and Marketing, at (513) 321-8404 or RReed@performanceplastics.com, more information on our EnduroSharp® kits and products.

-

Performance Plastics Injection Molds Fluoropolymers for Radome Applications

Fluoropolymers have a never-ending list of benefits in various material applications. They are virtually maintenance free, even in the most extreme conditions. At Performance Plastics, we know the value of Fluoropolymers. Fluoropolymers ensure safety, reliability and performance in numerous applications across major markets and cutting-edge technologies. Their electrical performance, weatherability, and optical properties make Fluoropolymers

Fluoropolymers have a never-ending list of benefits in various material applications. They are virtually maintenance free, even in the most extreme conditions. At Performance Plastics, we know the value of Fluoropolymers. Fluoropolymers ensure safety, reliability and performance in numerous applications across major markets and cutting-edge technologies. Their electrical performance, weatherability, and optical properties make Fluoropolymers ideal in telecommunication applications, including Radomes.

ideal in telecommunication applications, including Radomes.A Radome is used to protect the sensitive electronics in communication, telemetry and radar systems from environmental threats, UV damage and rapid fluctuations in temperature. The Radome structure protects the radar equipment, while also being transparent to the radio frequency systems, being used for signal transmission and capture without affecting the signal passing through them.

The material used to make a Radome has to with stand hard conditions, but also be transparent to radio frequency systems. Fluoropolymers are used to boost productivity and purity in an array of processes, helping manufacturers create

high-quality, cost-effective products. A Fluoropolymer material such as FEP, PFA or PVDF have the exact characteristics needed for a Radome application. Since other materials lack the chemical and temperature resistance and electrical performance of Fluoropolymers, they’re the number-one choice. At Performance Plastics, we have a unique ability to design and injection mold Fluoropolymers. We have developed a proprietary tooling and processes enabling the injection molding of FEP, PFA, or PVDF parts.

high-quality, cost-effective products. A Fluoropolymer material such as FEP, PFA or PVDF have the exact characteristics needed for a Radome application. Since other materials lack the chemical and temperature resistance and electrical performance of Fluoropolymers, they’re the number-one choice. At Performance Plastics, we have a unique ability to design and injection mold Fluoropolymers. We have developed a proprietary tooling and processes enabling the injection molding of FEP, PFA, or PVDF parts.To learn more about how Performance Plastics can help you with your project, contact Rich Reed, our Vice President of Sales and Marketing, at (513) 321-8404 or RReed@performanceplastics.com.

-

Performance Plastics Adds A New Kit To The EnduroSharp® Portfolio

Performance Plastics adds the C-130 Prop Hub Adhesive Removal Kit to the EnduroSharp® Product line. The EnduroSharp® C-130 Prop Hub Adhesive Removal Kit is used to safely remove adhesive from the propeller system. The Kit comes complete with a case of custom foam inserts that contain: 2 pneumatic tools, 1 Class I, Division 2 flash light, 1 contoured sharpening fixture (requires 120 – 180 grit abrasive paper, sold separately) and 4 EnduroSharp® Torlon® Scraper Blades (2 each left hand and 2 each right hand).

Performance Plastics is excited to offer this new kit to our customers. If you have any questions please contact Rich Reed, Vice President of Sales and Marketing, at (513) 321-8404 or RReed@performanceplastics.com

-

Performance Plastics’ Secrets to Seamless Mold Transfers

Having a mold made is a big investment for an OEM or brand owner of any size—a large enough outlay that it needs to be reliable the first time, every time. And once the tool is built and passes all tests, it’s up to the molder to ensure reliable parts are made on every cycle.

Truth be told, some molders are not able to use these tools effectively, devaluing this significant and time-intensive investment. At Performance Plastics in Cincinnati, we frequently see customers looking to transfer their molds because their previous molder couldn’t achieve production goals with the tool.

Why Transfer?

The main reason for transferring a mold comes down to the molder’s expertise. Generally, when a mold is transferred it’s because part consistency is

missing. Even if the molder makes improvements, the customer has to be able to trust its expertise and ability to solve problems right off the bat. A box of bad parts results first in a loss of confidence, followed by a lost order. There’s a saying: You only have one chance to make a good impression.

missing. Even if the molder makes improvements, the customer has to be able to trust its expertise and ability to solve problems right off the bat. A box of bad parts results first in a loss of confidence, followed by a lost order. There’s a saying: You only have one chance to make a good impression.At least half of Performance Plastics’ current client relationships started out with a mold transfer, including a tool that makes 1 million critical parts per year. With the previous molder, that customer was not getting consistent production and was worried that its products would fail in the field.

The Handoff

Like so many others, that million-part customer initially reached out to Performance Plastics to discuss mold transfer. But the first step in the process actually isn’t packing the mold into a crate and shipping it to our Cincinnati offices. The first step is defining the problem.

At least half of Performance Plastics’ current client relationships started out with a mold transfer

Before a company can understand why it’s not getting the type of product that it needs, it must know what it wants out of its finished product and what it should be able to do. Ask yourself: Do you know exactly what your product is and what it offers? Do you know all of its critical operations? You

cannot have a solution without a clearly defined goal.

cannot have a solution without a clearly defined goal.For example, your customer might need “Diameter A” to be perfect. However, production of the mold was driven more by another product feature.

Any qualified molder knows that it must understand what’s important to its customer and whether or not the customer is getting it out of the product. Define the problem; don’t just identify the symptoms.

Once the tool arrives, look at the project holistically and try to determine whether the problems described by the customer are related to the tooling, processing or molding capabilities of the prior molder. Review the tool completely, verifying tool steel, venting, cooling channels and any other pertinent aspects.

Once you have the mold in the press, utilize scientific injection molding principles to develop a process and set up the process-control variables to ensure that process is “locked in.” In some cases, the previous molders didn’t use a robust approach in working with the tool and just missed something. We’ve had some success at Performance Plastics identifying these types of mishaps by using our industrial computed tomography (CT) scanning equipment. By rotating the part 360° and using X-rays to create a precise 3D model, industrial CT scanning allows us to see the inner workings of a part without having to destroy it for inspection.

In addition to the application of scientific injection molding principles, use a design of experiments (DOE) to ensure you have identified the pertinent process-control variables and their limits. DOE is a branch of applied statistics that deals with the planning, conducting, analyzing, and interpreting of controlled tests to evaluate the factors that control the value of a parameter or group of parameters. At Performance Plastics, we use software that allows us to dial in and predict tolerances as they relate to process changes. DOE is a powerful data-collection and analysis tool that can be used in a variety of experimental situations. You need to know how multiple varying factors in a design interrelate and affect the results that you believe are important.

The Transfer Process

While transferring a mold from one supplier to another usually takes between two and six weeks, our experience has revealed it can actually be accomplished in as little as three days. Our engineering team works with the customer and its engineering department from the start to identify issues after the mold arrives.

At Performance Plastics, we have three in-house toolmakers that can handle mold modifications to correct errors and create fixtures and robotic end effectors if needed. In many circumstances, the prior molder and mold designer did not plan for adequate venting or they sized the mold to a poor process. After our trial runs, we are able to use our expertise in metrology to identify the best course of action.

We have a saying at Performance Plastics, “It’s not tight-tolerance unless you can measure it.” Once we know what we need to change, we work with our toolmakers to implement the plan. A lot of the timing revolves around the customer’s ability to supply its own clients. Since the mold is already in use and contracts have been signed, customers need to keep up their inventory of parts to meet demand, all while working to transfer the mold to another supplier who can use it more effectively.

We understand that it’s a painful process to transfer tools and switch suppliers. That said, we’ve handled more than 150 mold transfers over the years and know how to make the transition as seamless and painless as possible.

About the Authors:

Anthony Malone is VP of technology for Performance Plastics Ltd., a Cincinnati-based custom molder. With more than 25 years of experience in thermoplastics, Malone’s expertise extends into resin selection, part design and mold design. He works extensively with customers early in the product-design cycle to optimize part performance, manufacturability and life-cycle customer costs based on his extensive knowledge of advanced manufacturing techniques. Contact: amalone@performanceplastics.com.

Chris Lawson is COO of Performance Plastics and has more than 20 yr of experience with PPL. He started as a process engineer and then advanced through roles in quality, safety and manufacturing before assuming overall responsibility for operations. Lawson has specialized knowledge in the areas of automation (for production and inspection), vision systems, high-temperature polymers, process optimization and employee training. Contact: clawson@performanceplastics.com.

-

Performance Plastics Injection Molds Parts for Air Motors

The ability to mold unique and complex parts is what we take pride in a Performance Plastics. Our engineers are constantly pushing the limits of our machines and material in order to produce complex parts. We excel when using high performance plastics for challenging applications. Our most recent project we completed was injection molding vanes for various types of air motors.

Air motors produce continuous rotary power from compressed air. The vanes in the rotor cause the rotor to spin by sliding in and out when air is pushed into the rotor. The force differential created by the unbalanced force of

air on the vanes causes the rotor to spin in one direction. Vanes are extremely important when it comes to how the motor performs. The torque of the motor correlates to the vane surfaces and pressure of the air. Vanes undergo a lot of friction wear and pressure, making material choice for this project challenging.

air on the vanes causes the rotor to spin in one direction. Vanes are extremely important when it comes to how the motor performs. The torque of the motor correlates to the vane surfaces and pressure of the air. Vanes undergo a lot of friction wear and pressure, making material choice for this project challenging.Vanes need to be made from material that have high strength, low creep, resistance to high temperatures, low friction wear and resistant to water and organic compounds. Any deformity or wear in the vane will take away from the torque of the motor. Therefore, we had to choose a high-performance plastic that will

be able to handle the pressure of the compression inside the rotor without wearing or hindering the movement of the vane. The only two high performance plastic materials that fit the criteria are PEEK and Torlon®, two materials that we are experts in using at Performance Plastics. The mechanical properties in these high-performance plastics will allow for the vane effectively slide in and out of the rotor without causing damage to the vane.

be able to handle the pressure of the compression inside the rotor without wearing or hindering the movement of the vane. The only two high performance plastic materials that fit the criteria are PEEK and Torlon®, two materials that we are experts in using at Performance Plastics. The mechanical properties in these high-performance plastics will allow for the vane effectively slide in and out of the rotor without causing damage to the vane.To learn more about how Performance Plastics can help you with your project, contact Rich Reed, our Vice President of Sales and Marketing, at (513) 321-8404 or RReed@performanceplastics.com.

-

What drives the cost of making an injection mold?

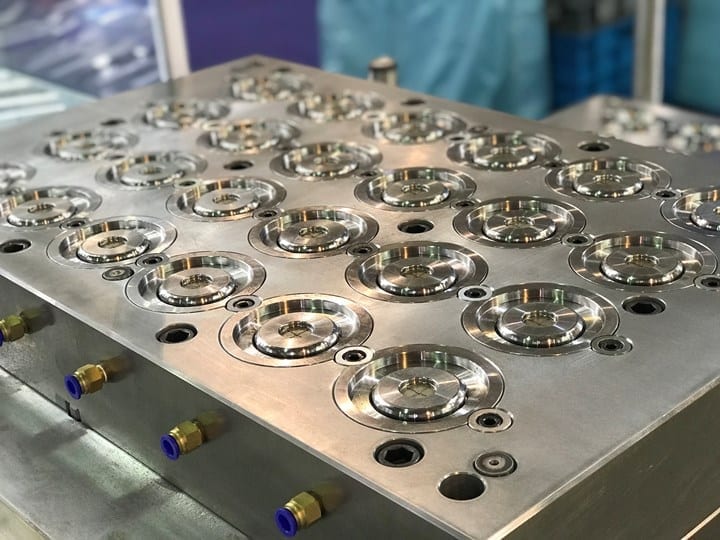

Before starting to manufacture a product, it’s important to decide on a mold for the injection molding process. This will directly influence the quality of your parts, and thus your final product. However, injection molds can quickly become rather expensive, with more complex, multi-cavity molds running as high as $70,000 or more. This drives up capital costs and can affect your bottom line if left unchecked.

At Performance Plastics, we know how important it is to maintain a seamless and efficient manufacturing process, both for design engineers and fiscal-minded partners. That’s why our team of process experts has determined the three key elements that drive the cost of injection molds:

fiscal-minded partners. That’s why our team of process experts has determined the three key elements that drive the cost of injection molds:- Molded part complexity and tolerances

- Mold material

- Where it’s made

Part Complexity and Tolerances

It’s simple – the more complex a part is and the more intricate geometry it has, the more it will cost. Complicated parts require equally complicated molds, not only from an overall layout and design perspective, but also from the surface finish of the final product and the number of required undercuts. The number of cavities you want your mold to have will also come into play here. A greater number of cavities is usually more efficient and cost effective but will drive up the price of each individual mold.Closely related to the complexity and geometry of a mold, the acceptable tolerances of a part will directly influence how precise a mold needs to be, and thus its cost. For example, pharmaceutical-grade components will naturally require stricter tolerances than something like a pocket comb or a commercial storage container, with tolerances less than .001” in “mission critical” applications.

Mold Material

When it comes to mold selection, materials matter. Generally, aluminum or steel are the go-to materials for injection molds. Aluminum molds are going to be cheaper and easier to get, but steel molds last longer and produce parts of a higher quality. Performance Plastics, has IP in mold metallurgy for mold challenging resins such as FEP and PFA. If you’re making a simple part and don’t need the mold to last you several years, then you can probably get away with an aluminum mold. Even though, steel molds have a higher upfront capital cost, their longer production life can save you time and money in the long run.What your part is going to be made out of will also influence the material selection for your mold. Certain materials like fiberglass can cause significant wear on a mold when injected under high pressures, making a more durable material like hardened steel a better option. If you’re working with fluoropolymers like PFA and FEP, you’ll need a mold that can handle their shear sensitivity, high melt temperatures, and fluorine outgassing. Performance Plastics offers a hot runner system and mold designed to minimize the shear forces inherent in the injection molding process, as well as proprietary metallurgy that’s highly resistant to fluorine gas corrosion.

Where It’s Made

Where a mold is made will impact its cost, both from a physical location standpoint and who the specific manufacturer is. Price deviations from one manufacturer to the next vary greatly, so you need to make sure that you read the fine print and know exactly the quality of mold that you’re getting. Molds can also be cheaper overseas, especially in China. However, molds built in Asia may add 25% to overall lead time. Performance Plastics has multiple approved mold builder sources globally as well as in-house capability. Remember, it’s the total cost of ownership of a mold that matters, not just the initial capital.To learn more about how Performance Plastics can help you find the right mold, contact Rich Reed, our Vice President of Sales and Marketing, at (513) 321-8404 or RReed@performanceplastics.com.

-

EnduroSharp® Order Form is Now Available Online!

EnduroSharp® Online Order Form, is now available to our customers. The new EnduroSharp® form is an interactive online form that gives our customers the ability to place an order or even request for a quote at their convenience. The form has all of our EnduroSharp® products and prices listed, just select the quantity amount on the box and you will see your total at the bottom of the page. If you are looking to request a quote, the online form will give you a total for the products you would like to quote, followed by an emailed copy of your quote. When placing an order the form will also, give you a total for the products you would like to purchase and provides an area for you to pay for the order with your credit card.

Performance Plastics is excited to bring this new offering to our customers. If you have any questions please contact Rich Reed, Vice President of Sales and Marketing, at (513) 321-8404 or RReed@performanceplastics.com.

-

Performance Plastics Supplies Essential Products for Covid-19

Performance Plastics is working hard to make products to fight against COVID-19. Production efforts from our stakeholders is vital to help our customers supply essential products to hospitals. The products supplied to the hospitals are critical medical devices such as oxygen concentrators, inhalation devices and IV system components.

Performance Plastics is working hard to make products to fight against COVID-19. Production efforts from our stakeholders is vital to help our customers supply essential products to hospitals. The products supplied to the hospitals are critical medical devices such as oxygen concentrators, inhalation devices and IV system components.The medical device field is something we specialize in at Performance Plastics. We excel in manufacturing components used in devices such as oxygen concentrators, inhalation devices and IV systems. These parts are made with high performance

plastics like polyetheretherketone, PEEK. The mechanical properties and flexural modulus of PEEK are among the highest of all plastic resins. PEEK’s properties provide resistance to abrasive and fatigue wear, even at elevated temperatures. The high-performance plastic is also not attacked by water or pressurized steam, making PEEK a reputable choice for use in medical devices.

plastics like polyetheretherketone, PEEK. The mechanical properties and flexural modulus of PEEK are among the highest of all plastic resins. PEEK’s properties provide resistance to abrasive and fatigue wear, even at elevated temperatures. The high-performance plastic is also not attacked by water or pressurized steam, making PEEK a reputable choice for use in medical devices.If you are interested in learning more contact Rich Reed, our Vice President of Sales and Marketing, at (513) 321-8404 or RReed@performanceplastics.com.

-

Performance Plastics Supports the Medical Industry During COVID-19

Performance Plastics injection molds custom products that support the medical industry. The parts we produce are critical to the medical field, especially now with COVID-19. Our dedicated team has been vital to our production, making sure our facility is safe, while also meeting our customer needs.

At Performance Plastics, we have extensive experience injection molding fluoropolymers such as, FEP and PFA. When supplying the medical industry, we use these fluoropolymers due to their

inert properties, high continuous use temperatures, organic compound compatibility, dielectric properties and resistance to atmospheric degradation. FEP and PFA are ideal for use in injection molded biomedical devices and thin-walled, complex parts such as vials, cuvettes, and test tubes used in our fight against the coronavirus.

inert properties, high continuous use temperatures, organic compound compatibility, dielectric properties and resistance to atmospheric degradation. FEP and PFA are ideal for use in injection molded biomedical devices and thin-walled, complex parts such as vials, cuvettes, and test tubes used in our fight against the coronavirus.

If you are interested in starting a project with us contact Rich Reed, our Vice President of Sales and Marketing, at (513) 321-8404 or RReed@performanceplastics.com.